| |

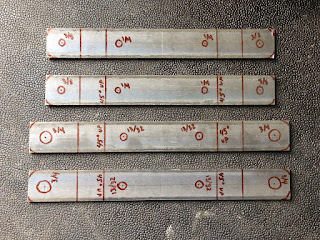

| July 20-22, 2014: Herein begins the construction of my revision C dynafocal engine mount. [ Click Here ] to get the plans (1:1 scale PDF). Dyanafocal is a contraction of Dynamic Focus. It's just a fancy way to say that the rubber shock mounts are oriented to be tangent to the arc of engine torque/vibration rotation, the center of which is the center of mass of the engine. These bars position and orient the rubber to be compressed in the correct direction with very little sheer force placed on the mounting bolts. As you can see above left, it starts out as a 48" long bar of 1-1/2" x 3/16" A36 hot rolled steel cut to the lengths given in the plans and marked for drill holes and bends. Above right shows the bars drilled and bent at a residential, one-man machine shop 5 miles away. The owner/operator, Ken Oliver, works on all sorts of hydraulic pump repairs and creates precision machined parts for antique gas-engines. Charged me $60 for his hour of time. Cost of the steel was $7, but $15 to ship, so overall, $85 (including gas and paint) for this portion of the mount. | |

Bottom dynafocal bars installed.

|

Upper dynafocal bars dry fitted for weighing. They will be installed on the engine, then the engine will be dropped in place. |

August 8, 2014

August 8, 2014So, after ordering and installing a new air screw o-ring (original was pretty battered), new enricher piston (original was probably just fine), new silicone fuel bowl gasket***, and new throttle cable and housing (originals were rusted enough to make moving the throttle hard and sticky), she STILL ran rich -- 4-stroking at ALL throttle settings. Silly me had installed the Bing 54 carb's main needle with circlip on TOP of (inside) the slider spring cup, instead of UNDER it. Once I changed its position, she fired right up and purred like a kitty, just like she was doing when she abruptly fell silent on October 26, 2009. Lesson learned? Or will I forget this again? *** I ordered them from RealGaskets.com. I strongly advise that you DO NOT GET them, because they swell up by nearly 5% after only a day exposed to gasoline, which makes it impossible to re-seat, UNLESS you buy two of them. They DO return to normal size after drying out for a day or two, so plan your visit to the inside of the fuel bowl carefully so you always have one dry gasket available. |

Installed a bubble-type carb fuel primer (the kind used on weedwackers and other gas-powered equipment), because two plunger-style primers that I previously mounted in the cockpit instrument panel leaked from a seam in the plunger body, despite being brand new, so I wasn't going to go down that road again.

Installed a bubble-type carb fuel primer (the kind used on weedwackers and other gas-powered equipment), because two plunger-style primers that I previously mounted in the cockpit instrument panel leaked from a seam in the plunger body, despite being brand new, so I wasn't going to go down that road again.

Super nice. Wish I could find a reasonable priced Rotax for my project...

ReplyDeleteMe Too....

ReplyDeleteWill this type mount work with a kawasaki 440, this engine was mounted hanging , can it be mounted on top? I know this is a sky hopper blog, but it seems you would be a person that could really help me get in the air.

ReplyDeleteWorks for any engine, just have to adjust hole spacings for the engine (top bar) and frame (bottom bar) attachments. The Barry mounts holes must remain the same in order for them to mate up.

ReplyDeleteI need a set of those motor mounts for my 447 Rotax. Do you have a contact name and number for the fabricator? Glad to pay $85. for those. Thanks..Rick

ReplyDeleteAnd...what about the dynafocal mount? Are you getting less vibration with it?

ReplyDeleteIt's hard to tell without the old, straight bar mount to compare to. I mean, anything that vibrates hard enough is going to transfer that energy into the structure supporting it, no matter how much rubber is used or how it's oriented.

Delete